- Comment

(0)

Home > News > 3D printing

Evonik launches new TPA elastomer powder material for SLS 3D printing

Evonik extended its portfolio of elastomeric materials for powder bed fusion 3D printing technologies with INFINAM TPA 4006 P.

Properties and features of new elastomer powder

The new powder grade is a PA12 elastomer, consisting of polyamide 12 segments and softening segments. It is characterized by rubber-like properties and outstanding impact strength, and thus exhibit excellent rebound behavior.

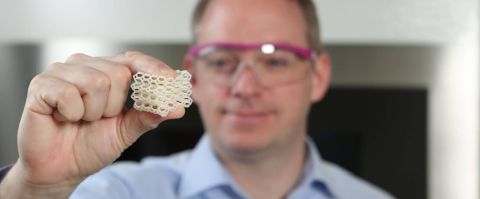

New INFINAM TPA 4006 P exhibit excellent rebound behavior.

Evonik’s new 3D printing elastomer features high process stability and outstanding powder flow properties, making the material perfectly suitable for all types of selective laser sintering (SLS) technologies.

Furthermore, the fine powder can be manufactured with reusability rates of 50/50 virgin versus used material.

High performance and extended application

3D printed parts with INFINAM TPA 4006 P show excellent surface resolution and feature detail, as well as exhibiting outstanding durability over a wide temperature range of 40-90°C.

TPA has been used for decades as material of choice for a variety of consumer goods applications like footwear. Moreover, the powder material also ideally fits for manufacturing functional 3D high-tech plastic parts, for both prototypes and series products.

Comprehensive range of elastomeric 3D printing materials

Evonik’s range of elastomeric printing materials includes two types of powder – thermoplastic amide INFINAM TPA and thermoplastic copolyester INFINAM TPC, for powder bed fusion 3D printing technologies.

Another rubber-like photopolymer resin – INFINAM FL, for photo-curing 3D printing, completes the company’s portfolio of elastomeric materials for industrial 3D printing.

Like

Like

Leave Comment

All Comments

Recommended Articles

3D printing

3D printing 2025-01-06

2025-01-06 管理员

管理员 3D printing

3D printing 2024-11-20

2024-11-20 3D printing

3D printing 2024-11-14

2024-11-14 3D printing

3D printing 2024-11-04

2024-11-04 3D printing

3D printing 2024-10-23

2024-10-23 3D printing

3D printing 2024-10-18

2024-10-18You May Also Like

Must See

Must See

1

1 2

2 3

3 4

4 5

5

- Hot Specials

You May Be Interested In

Change

- People

- Company

Hot Tags

Subscribe To Tags, See What You Want To See

Subscribe To Tags, See What You Want To See Sign Up For Events, Expand your network

Sign Up For Events, Expand your network Unlock Private Messages, Participate In Interactions

Unlock Private Messages, Participate In Interactions